Tube clamp connectors

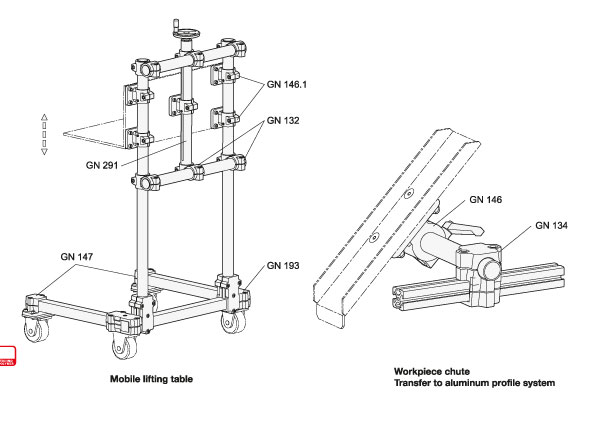

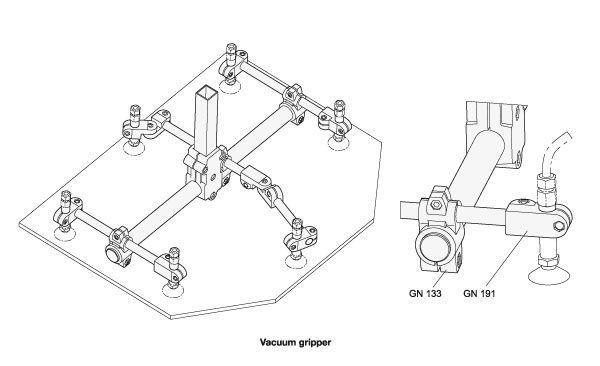

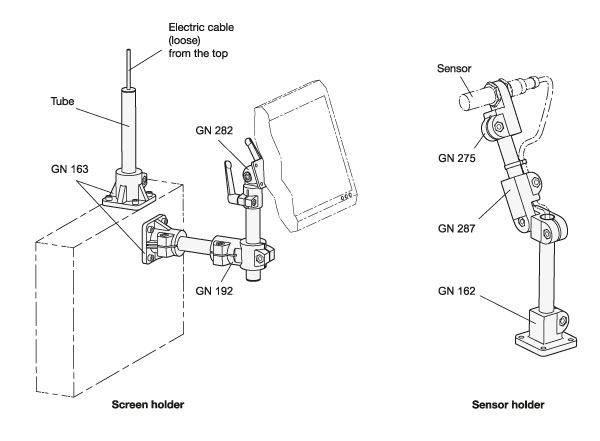

Tube clamp connectorsare clamping components made ofaluminumorStainless Steelwhich offer the facility for simply and rapidly constructing jigs, fixtures and operating systems using standard round and square section tubings.

The vast range of clamp connectors in split monoblock or multi-part form offer almost unlimited possibilities.

Split monoblock clamp connectors give very robust and sturdy tubular constructions. For this purpose only precision tubings DIN 2391, with an outside diameter which lies within relatively tight tolerances, should be used. (Construction tubes GN 990 see page 1902).

Multi-part clamp connectors (consisting of two or more separate parts) are not tied to tight tolerances as they can be used with square tubes (Construction tubes GN 990 see page 1902) thus allowing incorporation into already existing systems.

As clamping screws there is a choice of either cap head screws to DIN 912 or adjustable clamping kits GN 911 if repeated removal and re-installation is required. As for nuts, hexagon nuts DIN 985 (ISO 10511) which are self-locking with polyamide ring are recommended.

The clamping points are provided onboth sideswith sockets, cast in the component, which give a free choice for positioning hexagon nuts and clamping connectors.

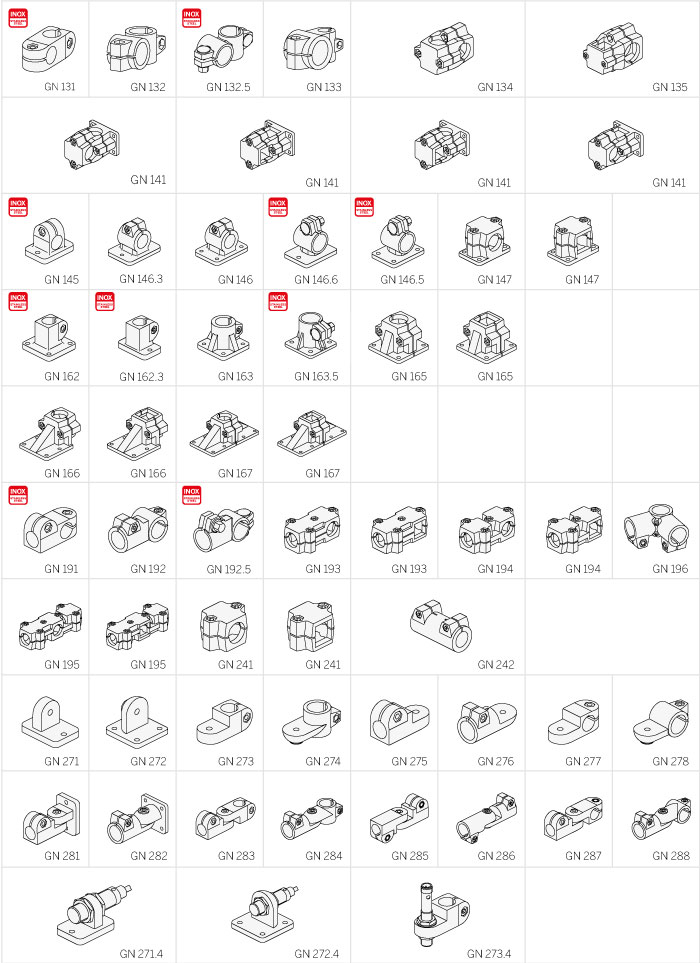

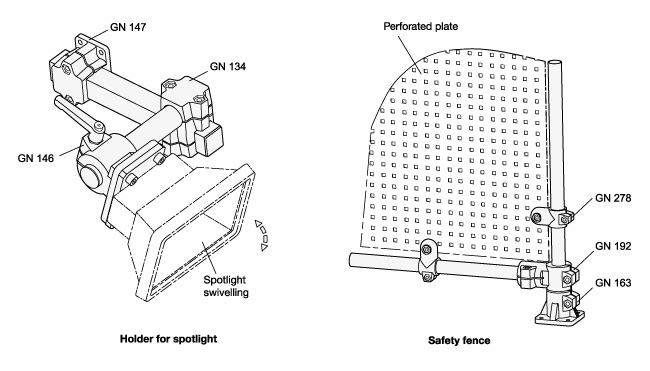

Within the tube clamp connectors range there are numerous clamping components available...

The tube clamp connector program offers a wide range of components that can be used in connection withlinear actuators(tubes with adjustable spindle) see page 1910 and following pages.

- Two-way connector clamps

- Flanged two-way connector clamps

- Flanged connector clamps

- Base plate connector clamps

- Flanged base plate connector clamps

- T-Angle connector clamps

- Tube connectors

- Swivel clamp connectors

- Swivel clamp connector joints

- Sensor holders

-

Generals

-

1. Plastic materials

- 1.1 Mechanical strength

- 1.2 Thermal resistance

- 1.3 Strength and surface hardness

- 1.4 Resistance to chemical agents

- 1.5 Resistance to atmospheric agents and uv rays

- 1.6 Flame resistance

- 1.7 Electrical properties

- 1.8 Surface finish and cleanability

- 1.9 Compliance with international standards

- 1.10 Competence of Elesa+Ganter technical department

- 2. Metal materials

- 3. Other materials

- 4. Machining tolerances

- 5. Fixed handles

- 6. Assembly measures

- 7. Special executions

- 8. Colours

- 9. Test values

-

10. Technical tables

- 10.1 Conversion tables

- 10.2 DIN 79 Square holes and shafts

- 10.3 DIN 6885 Keyways

- 10.4 GN 110 and GN 110.1 Transversal holes

- 10.5 DIN 13 ISO Metric threads

- 10.6 DIN 228 Cylindrical GAS-BSP threads

- 10.7 DIN EN ISO 898-1 | DIN EN 20898-2 Strenght values

- 10.8 DIN ISO 286 ISO-Fundamental tolerances

- 10.9 IP Protection Classification

- 10.10.1 PFB | PRB Thread locking with jamming action Polyamide patch coating/ Polyamide complete coating

- 10.10.2 MVK Thread locking gluing Micro encapsulation precote 80 (red)

- 10.11 Stainless Steel characteristics

- 10.12 Surface treatments

- 10.13 Carbon steel, zinc alloys, aluminium, brass characteristics

- 10.14.1 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.2 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.3 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.15 Load ratings U-Handles

- 10.16 Load ratings metal hinges

- 10.17 Strength of indexing plungers

- 10.18 Assembly sets GN 965 and GN 968

- 11. Vibration-damping elements

-

1. Plastic materials

- Hygienic design

- Operating Elements

- Clamping knobs

- Control elements

- Rotary controls

- Indexing elements

- Joints

- Transmission elements

- Levelling elements

- Hinges

- Latches

- Toggle, power and hook clamps

- Accessories for hydraulic systems

- Tube clamp connectors

- Castors and wheels

- Magnets

- Conveyor components

- Linear slides

- Vibration mounts

- Vacuum components

- Elastomer springs