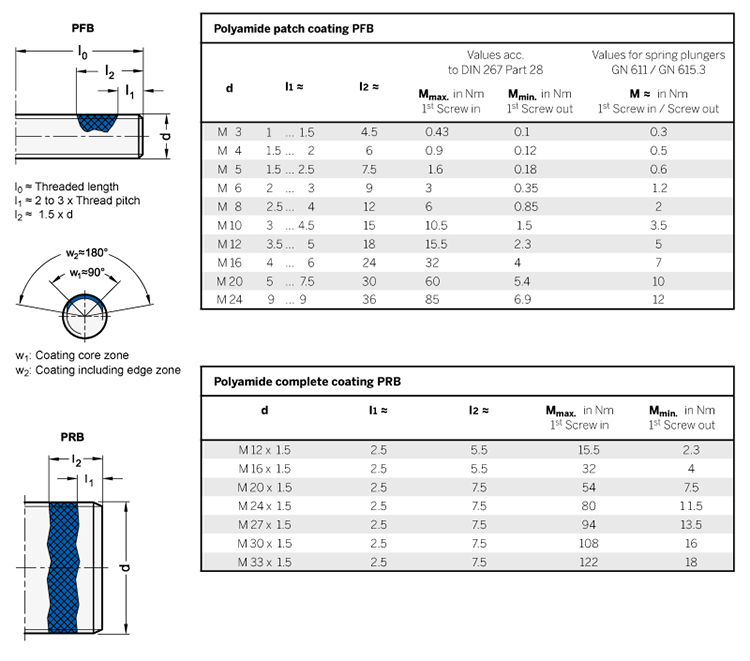

PFB | PRB Thread locking with jamming action Polyamide patch coating/ Polyamide complete coating

The torque values are based on a test of a thread without preload with a nut thread 6H at room temperature. For PFB and thread lenghts l0 < l2, l2 is reduced in such a way that one to two thread turns are not coated at the end of the thread.

Description

The polyamide patch coating PFB is a process whereby an elastic plastic material (Polyamide) is applied to a part of thread which creates a jamming action during the tightening of a nut. The coating can be produced either as a patch or complete coating. The axial play between the bolts and nut thread is taken up by the polyamide thus ensuring maximum surface pressure between the opposite uncoated thread flanks. This process counteracts the loosening and unscrewing on their own. There is no cure time required, the thread contact is instantaneous resilient. The typical spray edge zone of the polyamide deposit prevents shear blasting.

Features

– High thread locking action, shakeproof. Excellent convenient for adjusting bolts.

– The locking system is a captive component of the standard part, which eliminates the fitting of additional belay.

– Temperature resistant from – 60 °C up to 120 °C

– Approval for food areas

– High chemical stability

– Use is also possible, for instance, in oil-contaminated threaded holes

– Multi use is possible whereby the jamming effect after the 5th removal is around 50 % of its original strength.

Information

Polyamide patch coating is offered for GN 615.3 (see page 840) spring plungers. A blue coating indicates type K or KN, green indicates type KS or KSN (high spring load). Polyamide complete coating is available for GN 252 and GN 252.5 blanking plugs (see page 1685) as a type.

-

Generals

-

1. Plastic materials

- 1.1 Mechanical strength

- 1.2 Thermal resistance

- 1.3 Strength and surface hardness

- 1.4 Resistance to chemical agents

- 1.5 Resistance to atmospheric agents and uv rays

- 1.6 Flame resistance

- 1.7 Electrical properties

- 1.8 Surface finish and cleanability

- 1.9 Compliance with international standards

- 1.10 Competence of Elesa+Ganter technical department

- 2. Metal materials

- 3. Other materials

- 4. Machining tolerances

- 5. Fixed handles

- 6. Assembly measures

- 7. Special executions

- 8. Colours

- 9. Test values

-

10. Technical tables

- 10.1 Conversion tables

- 10.2 DIN 79 Square holes and shafts

- 10.3 DIN 6885 Keyways

- 10.4 GN 110 and GN 110.1 Transversal holes

- 10.5 DIN 13 ISO Metric threads

- 10.6 DIN 228 Cylindrical GAS-BSP threads

- 10.7 DIN EN ISO 898-1 | DIN EN 20898-2 Strenght values

- 10.8 DIN ISO 286 ISO-Fundamental tolerances

- 10.9 IP Protection Classification

- 10.10.1 PFB | PRB Thread locking with jamming action Polyamide patch coating/ Polyamide complete coating

- 10.10.2 MVK Thread locking gluing Micro encapsulation precote 80 (red)

- 10.11 Stainless Steel characteristics

- 10.12 Surface treatments

- 10.13 Carbon steel, zinc alloys, aluminium, brass characteristics

- 10.14.1 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.2 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.3 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.15 Load ratings U-Handles

- 10.16 Load ratings metal hinges

- 10.17 Strength of indexing plungers

- 10.18 Assembly sets GN 965 and GN 968

- 11. Vibration-damping elements

-

1. Plastic materials

- Hygienic design

- Operating Elements

- Clamping knobs

- Control elements

- Rotary controls

- Indexing elements

- Joints

- Transmission elements

- Levelling elements

- Hinges

- Latches

- Toggle, power and hook clamps

- Accessories for hydraulic systems

- Tube clamp connectors

- Castors and wheels

- Magnets

- Conveyor components

- Linear slides

- Vibration mounts

- Vacuum components

- Elastomer springs